Measuring the frictional coefficient between two surfaces is a well-established task, performed for centuries through both experiments and simulations.

However, the inverse problem—designing a surface that yields a desired frictional coefficient—is far more challenging. We refer to this task as inverse frictional design. Traditional approaches rely on computationally intensive algorithms and deep physical insight.

Here, we propose a novel machine learning approach using a conditional diffusion model to generate surfaces that exhibit target frictional properties.

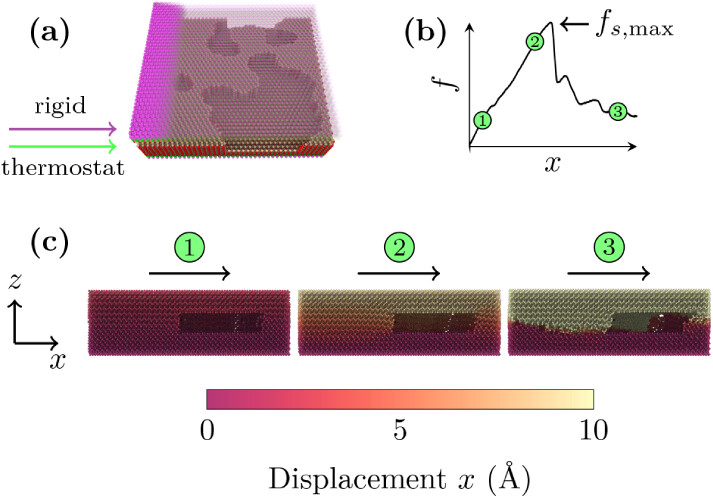

Molecular dynamics simulations are used to evaluate the frictional properties of generated surfaces.

Methodology

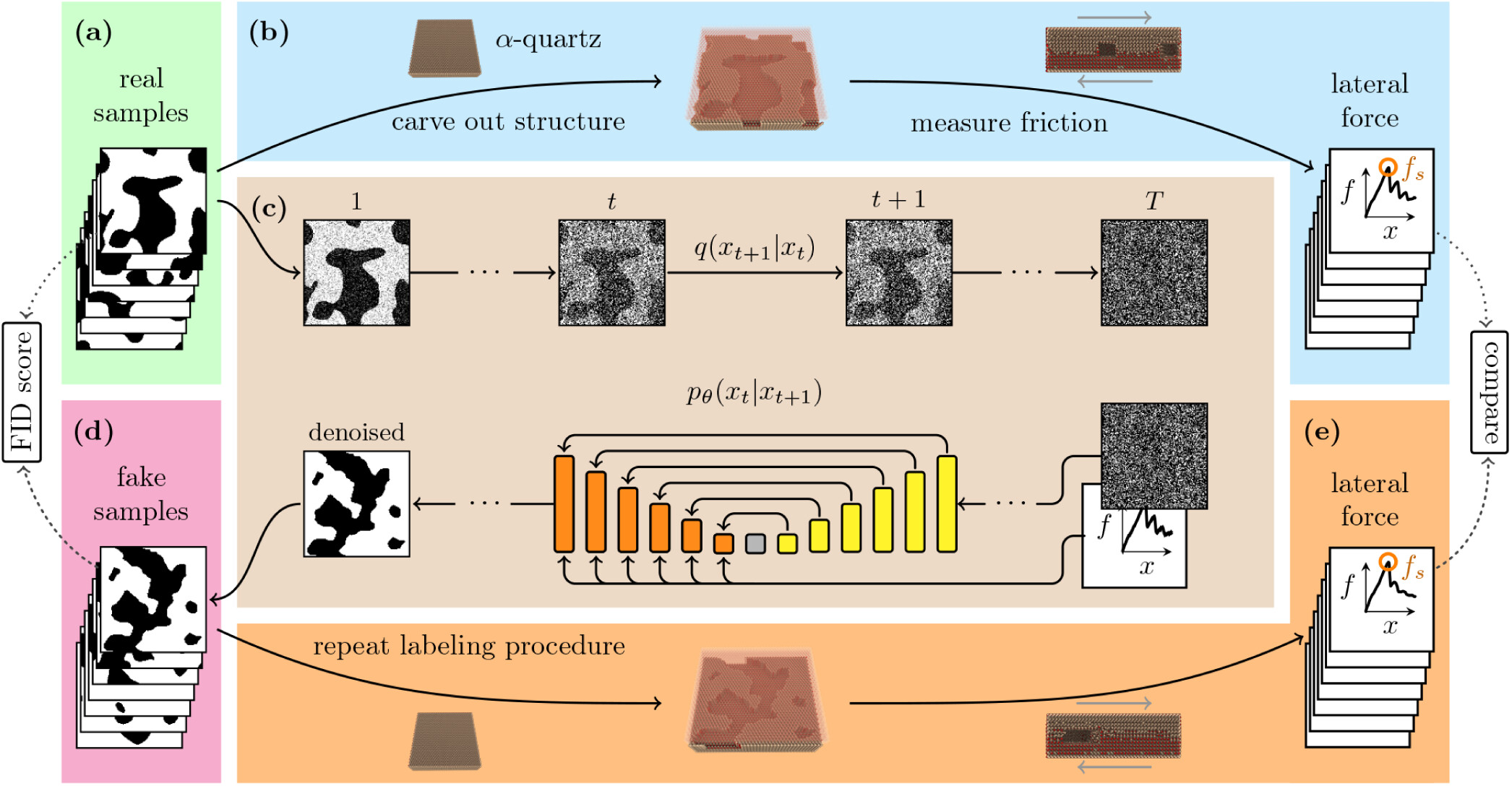

Our approach falls within the category of generative AI, borrowing techniques from image synthesis. Specifically, we use a diffusion model capable of iteratively denoising a random sample until it matches the learned distribution.

In this context, the sample corresponds to a surface topography, and the model is conditioned on the static friction force. Similar strategies have recently been applied in material science, such as by Bastek & Kochmann (Bastek & Kochmann, 2023).

Dataset

To construct our training dataset, we generated surface topographies using simplex noise (Perlin, 2002), which produces visually realistic structures.

Each surface served as the initial condition for molecular dynamics simulations, where we measured the resulting static friction force.

The dataset—comprising 10,000 surfaces paired with frictional measurements—represented the most computationally demanding part of this work.

Methodology overview.

Model Training

We employ a UNet architecture as the denoising backbone of our diffusion model.

Once trained, the network can generate a surface designed to exhibit a specified static friction force.

We validate this by simulating the generated surfaces and comparing the measured friction to the target values.

Results

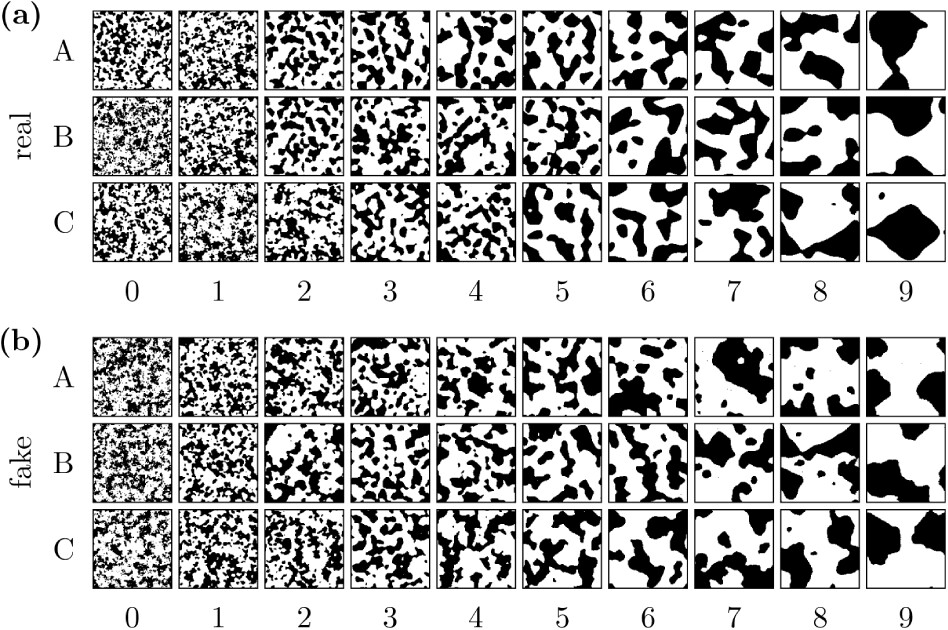

The generated surfaces closely match the desired static friction forces.

Comparison between real surfaces (upper three rows) and generated surfaces (lower three rows).

Interestingly, we find that cluster size is the dominant factor affecting friction when the real contact area is standardized.

Contrary to common expectations, a few large contact clusters produce stronger frictional interfaces than many small ones.

Read the full article here:

EM Nordhagen, HA Sveinsson, A Malthe-Sørenssen.

Tailoring Frictional Properties of Surfaces Using Diffusion Models.

The Journal of Physical Chemistry C (2025).

References

- Perlin, K. (2002). Improving Noise. ACM Transactions on Graphics, 681–682. https://doi.org/10.1145/566570.566636

- Bastek, J.-H., & Kochmann, D. M. (2023). Inverse design of nonlinear mechanical metamaterials via video denoising diffusion models. Nature Machine Intelligence, 5(12), 1466–1475. https://doi.org/10.1038/s42256-023-00762-x